Over the years, Flonal has reached a very high level of automation and technology through processing islands which include various production steps managed by a single operator: robotised feeders which permit greater productivity and utmost control of the semi-finished product, 5.000-ton hydraulic presses for cold-pressed forging, spray and roller systems which make it possible to apply any type of coating existing today on the market, including silk-screen stations for marking the products.

Technology

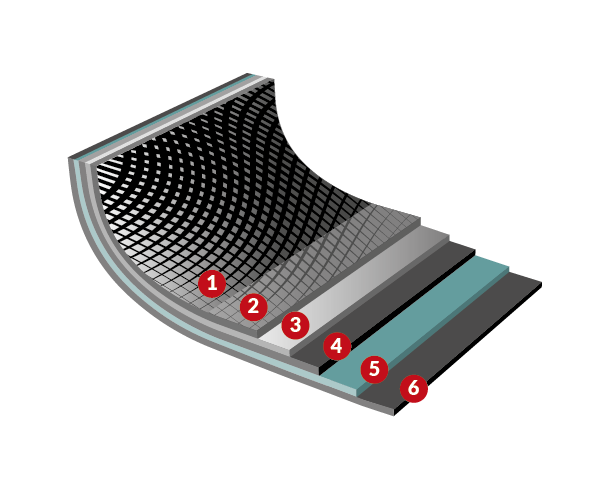

Diamond Coating Technology

Super hard material for the best performances

Thanks to the cooperation with Greblon, Flonal develops its first coating reinforced with real diamonds. Designed for professional use, DCT is a very high efficient technology that ensures outstanding non-stick effect and durability. Characterized by a high degree of hardness, it is strong against wear and scratches over time. The coating is doubly reinforced with real diamonds: thirty-three carats every kilogram of dried coating. This technology reinforces the mid coat, increasing the thickness up to 60 microns. One of the hardest and most resistant materials in nature is used to guarantee the best performances and a long life.

* 15 CARATS EVERY KILOGRAM OF COATING (THAT EQUALS TO 33 CARATS EVERY KILOGRAM OF DRIED COATING)

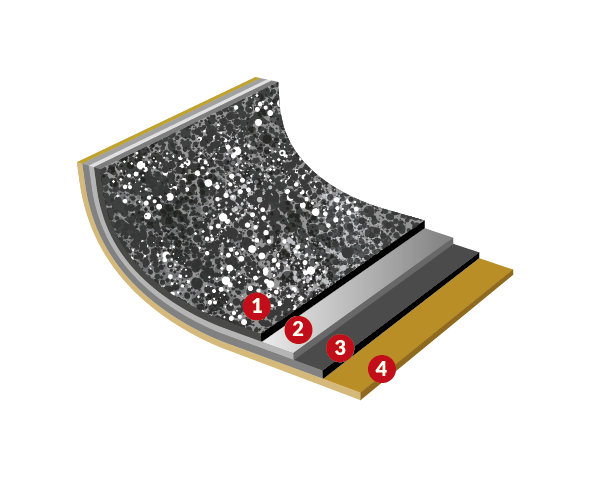

Magma-Tech Plus

Even harder and more durable

Magma-Tech Plus (45 ± 5 μ thickness) is a coating designed to achieve outstanding performances during cooking. Its special formula guarantees a very high wear and scratch resistance, 35% more than the previous version. Specific mineral reinforcements, of various size and shape, are combined to create an impenetrable protection, metal proof. A strong and solid structure that, together with the higher thickness of the film, ensures the preservation of incredible non-stick properties over time.

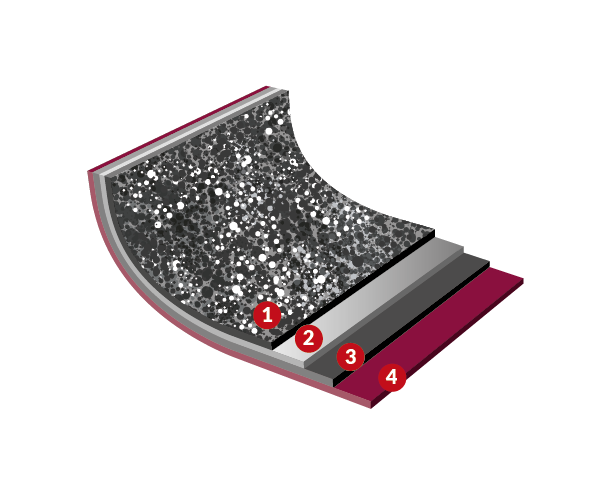

Magma-Tech

Hardness and durability over time

The Magma-Tech coating (35 μ thickness) is designed to offer a high wear and scratch resistance. The mineral particles that are added to the coating constitute a real barrier that protects the coating itself even when using metal kitchen tools. A coating able to guarantee stable performances over time.

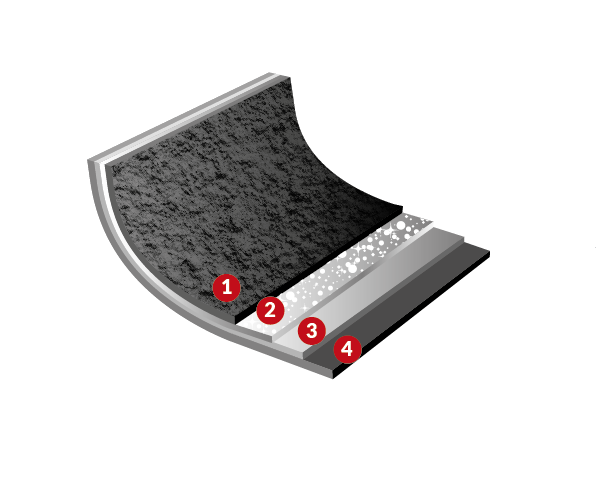

Pb-Tech

The extra layer that makes the difference

Protective Barrier is a technique that can apply, between the traditional coating layers, a special layer made of extra resistant material able to create roller non-stick coatings with properties never seen before. Thanks to a double firing process, a greater quantity of non-stick is released on the product, to guarantee a more efficient maintenance of the properties, compared to similar coatings. A combination of ceramic and mineral particles that creates a real barrier against scratches and abrasions.

Cera-Tech

Lower environmental impact

The Cera-Tech coating, made of special silicon particles, creates an extremely compact film that guarantees an excellent resistance against scratches, abrasions and high temperatures. Furthermore its extremely smooth and non-porous surface enhances its non-stick properties making it a practical and easy product to clean. The production cycle of Cera-Tech is achieved at low temperatures permitting notable savings in energy and consequently a reduction in the emissions of CO2 .

This supports an environmentally sustainable production, on which Flonal has always placed great importance.

Heat Tech

Efficient induction technology

Heat Tech is the new frontier of induction. It originates from an accurate study of the shape and design of the magnetic induction bottom, aimed at optimizing the heating process of the pan, taking care of practicality and comfortability during use. The result is an extremely high performing base, which ensures a fast and homogeneous distribution of the heat during cooking.

Declaration State of California Assembly Bill No. 1200

State of Maine H.P. 1113 – L.D. 1503

Based on current knowledge we hereby confirm that the non-stick coating films of all our products, applied in accordance with the specifications and instructions of our suppliers, do contain the following intentionally added substances listed in the updated authoritative list of the Department of Toxic Substances Control dated November 16th, 2022.

California Assembly Bill No. 1200

PFASs Perfluoroalkyl and Polyfluoroalkyl Substances max 600mg/dm²

Maine H.P. 1113 – L.D. 1503

Polytetrafluoroethylene CAS N° 9002-84-0 max 600mg/dm²

Perfluoroalkoxy Alkane CAS N° 26655-00-5 max 20mg/dm²

Fluorinated Ethylene-Propylene CAS N° 25067-11-2 max 10mg/dm²

Declaración Estado de California Proyecto de ley de la Asamblea nº 1200

Estado de Maine H.P. 1113 – L.D. 1503

Basándonos en nuestros conocimientos actuales, confirmamos por la presente que las películas de revestimiento antiadherente de todos nuestros productos, aplicadas de acuerdo con las especificaciones e instrucciones de nuestros proveedores, contienen las siguientes sustancias añadidas intencionadamente que figuran en la lista autorizada actualizada del Departamento de Control de Sustancias Tóxicas con fecha 16 de noviembre de 2022.

Proyecto de ley de la Asamblea de California nº 1200

PFASs Perfluoroalkyl and Polyfluoroalkyl Substances max 600mg/dm².

Maine H.P. 1113 – L.D. 1503

Politetrafluoroetileno CAS N° 9002-84-0 máx 600mg/dm²

Perfluoroalcoxi alcano nº CAS 26655-00-5 máx. 20mg/dm².

Etileno-propileno fluorado nº CAS 25067-11-2 máx. 10mg/dm².